One of the wonderful things about concrete is that it works in two (or even 3) directions simultaneously. While buildings constructed of steel or wood generally have a system of beams and joists to create the floors, concrete buildings can have a single flat slab supported by widely spaced columns. This lets architects design open spaces with clean lines and simple support patterns.

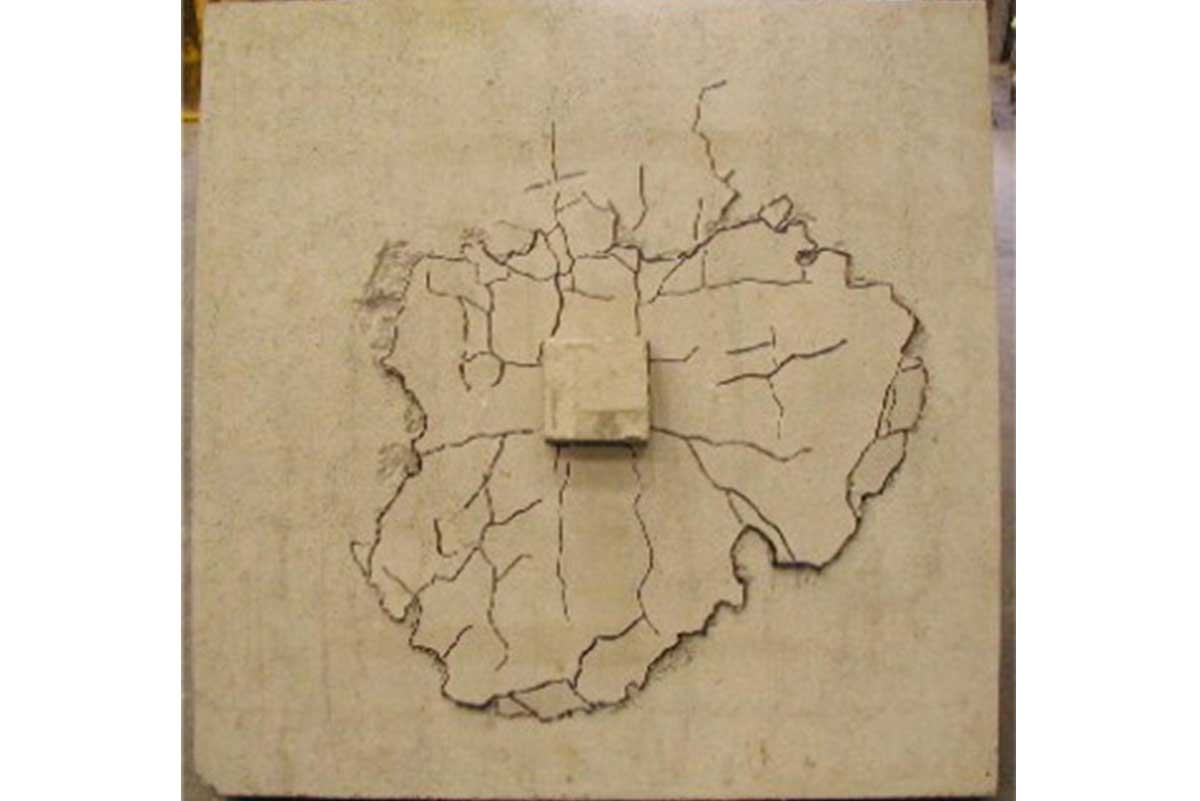

Unfortunately, when it comes to engineering, nothing is free – those clean lines and open spaces come at the price of large loads at the columns. So large, in fact, that one of the major concerns that engineers have is the column hammering through the slab like a toddler’s finger through a peanut-butter-and-jelly sandwich. This load is called punching shear.

Punching shear is a function of the load applied, the strength of the concrete, the depth of the slab, and the size of the column. Designers faced with punching shear issues can increase the strength of their concrete (adding cost), increase the size of the columns (reducing the amount of usable space while increasing both the amount of concrete and steel used in the column) or thicken the slab. Since thickening the entire slab is even more expensive, designers generally design a small drop capital (or “drop cap”). This cap must be large enough that it doesn’t punch through the slab, and thick enough that the column doesn’t punch through it. The formwork and reinforcement detailing for these is fairly involved as well, not to mention spoiling the clean lines the architect was hoping for.

Since post-tension slabs are generally thinner than conventionally-reinforced slabs, Advanced Post-Tension is familiar with all these design issues and trade-offs. We supply stud rails on many of our jobs, and consider them to be the most cost-effective method of addressing punching shear on elevated post-tension slabs. We’re happy to discuss the design and detailing issues that arise from the use of this system.